On September 14, Chairman Ho Minh Hoang and the Advisory Council members checked the construction progress of Binh Dinh Coastal Road and Quang Ngai - Hoai Nhon Expressway.

The Binh Dinh Coastal Road Project has achieved 40% construction progress, exceeding the required plan by 20%. To optimize machinery usage, the Board of Directors has planned for overtime work, which speeds up progress and saves costs and reduce waste.

Inspection of construction of Binh Dinh Coastal Road project

The Chairman praised the responsible optimization of production to save costs and requested the executive board to assess the effectiveness of the equipment usage method for replication in future projects. Mr. Ho Minh Hoang requested that the board prioritize the well-being of on-site employees, facilitate knowledge exchange, and provide training opportunities for dedicated personnel to improve their qualifications and skills.

At the Quang Ngai - Hoai Nhon Expressway project, the entire project had mobilized more than 2,400 personnel, 965 equipment and deployed 38/43 construction teams. Implemented output reached 750/12,983 billion VND.

The Board Chairman gave payment acceptance instructions in a recent meeting, and the board plans to accept 332 billion VND by September 2023, with 32% remaining in progress.

Inspection of construction of Quang Ngai - Hoai Nhon project

"As a joint venture leader and general contractor, good construction organization and effective management of other contractors, including controlling the value of unfinished work, are essential", Chairman Ho Minh Hoang noted.

Vice Chairman Nguyen Tan Dong stated that the new construction method for tunnel 2 allows for a daily digging speed of 7m, which, combined with geological considerations, will ensure completion of the tunnel by the end of this year.

In addition to innovative in tunneling methods to speed up progress, also in tunnel No. 2, the Steering Committee has researched the solution of using filtered tunnel drilling water for reuse, saving time and cost.

Engineer Bui Hong Dang, Managing Director of XL2 package, stated that there is almost no water in this area from September to November, while 100 cubic meters/day of water is required for tunnel drilling. To address this, the Board of Directors researched and implemented a method of collecting, filtering, and reusing drill water, which reduces daily water consumption to less than 5 cubic meters by utilizing about 95% of the tunnel drilling water.

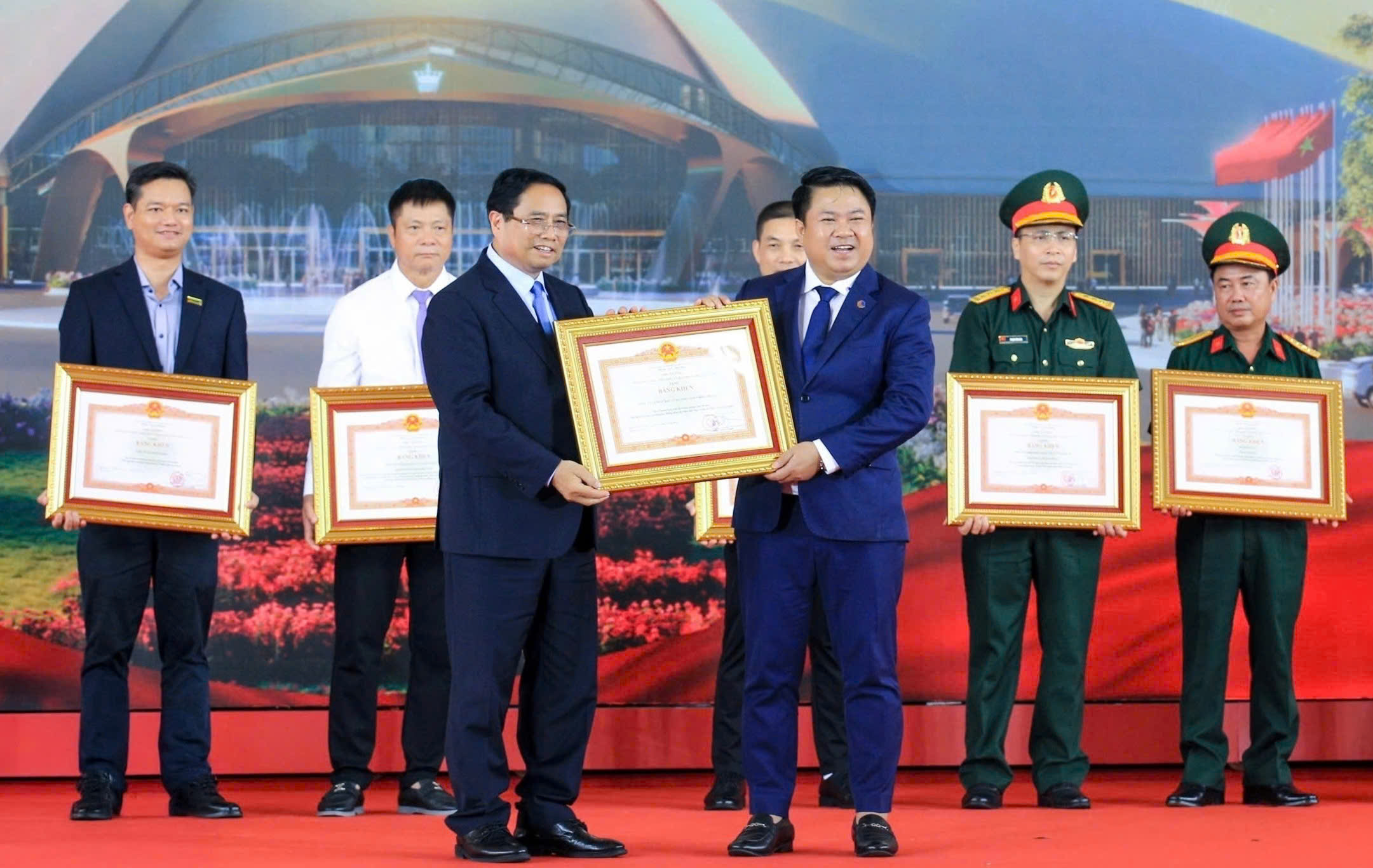

After hearing Engineer Bui Hong Dang's report on the "recycled" water method, Mr. Ho Minh Hoang promptly rewarded Engineer Dang and the implementation team to encourage the creative spirit of the engineers and workers on the construction site.

TT